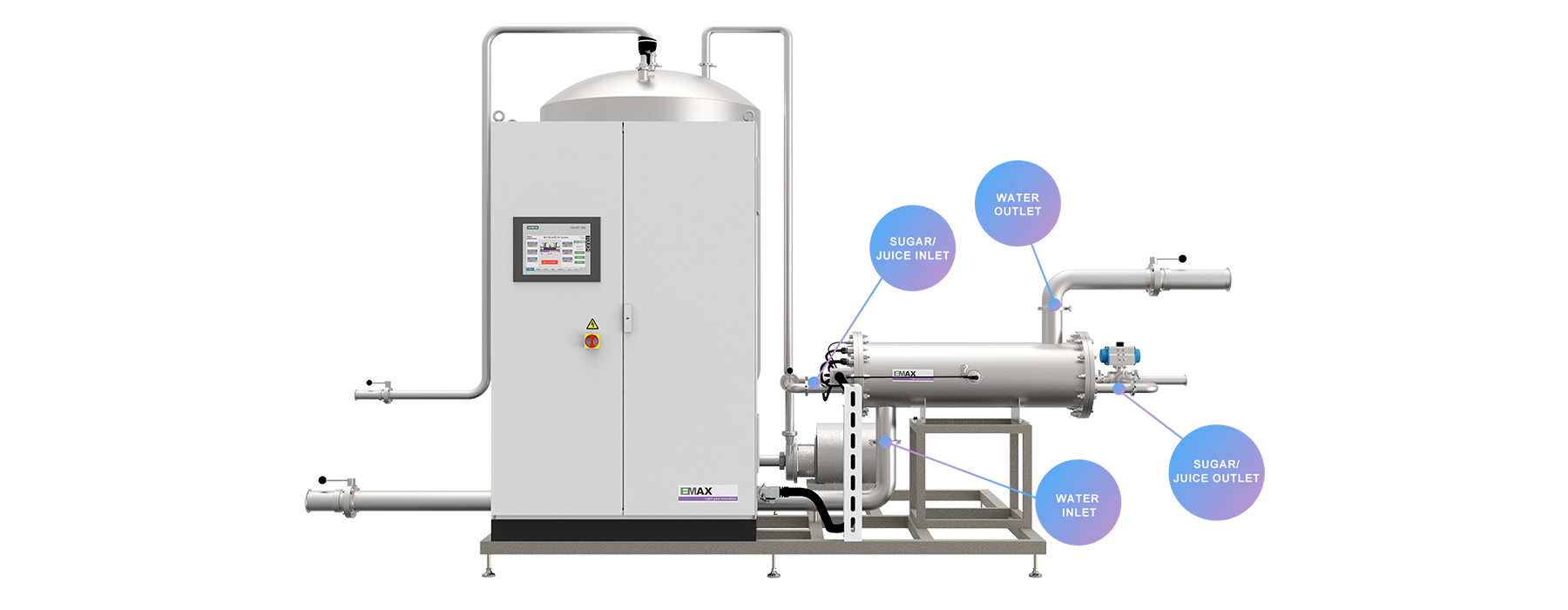

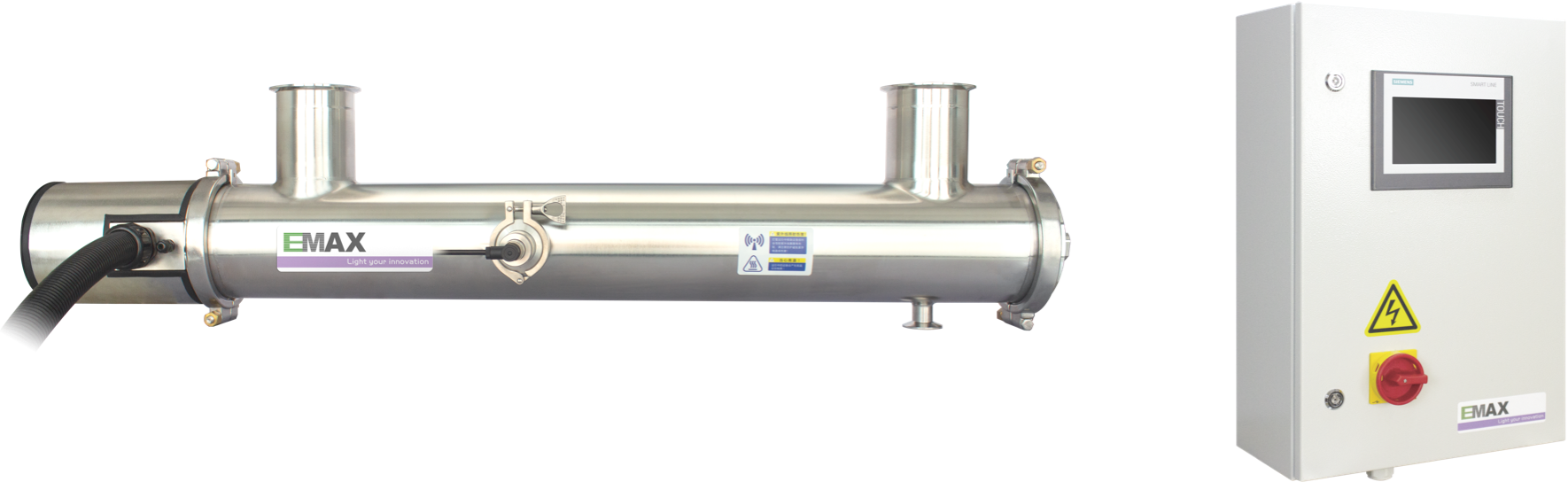

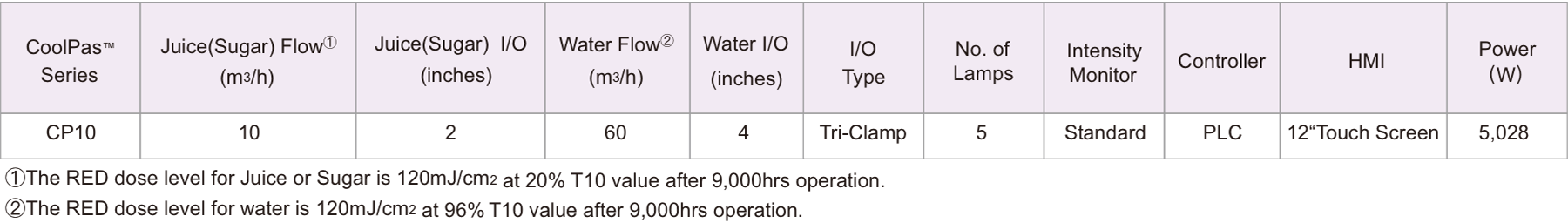

CoolPasTM Cold Pasteurization for Juice/Sugar syrup and Water

Disinfection is a key process in juice and beverage production. Conventional disinfection methods usually involve high temperature, including pasteurization, UHT, etc. A dilemma lies in these processes: if the temperature of the process is not high enough, the microbes won't be killed completely. On the contrary, if the temperature is too high, it will effectively kill all the microbes but impact the freshness and nutrition of the juice adversely. In addition to these facts, both the capital cost and the running cost of Pasteurization systems are very high.

Cold Sterilization process is a perfect solution to assuring the freshness and meanwhile extending the shelf life of the products.

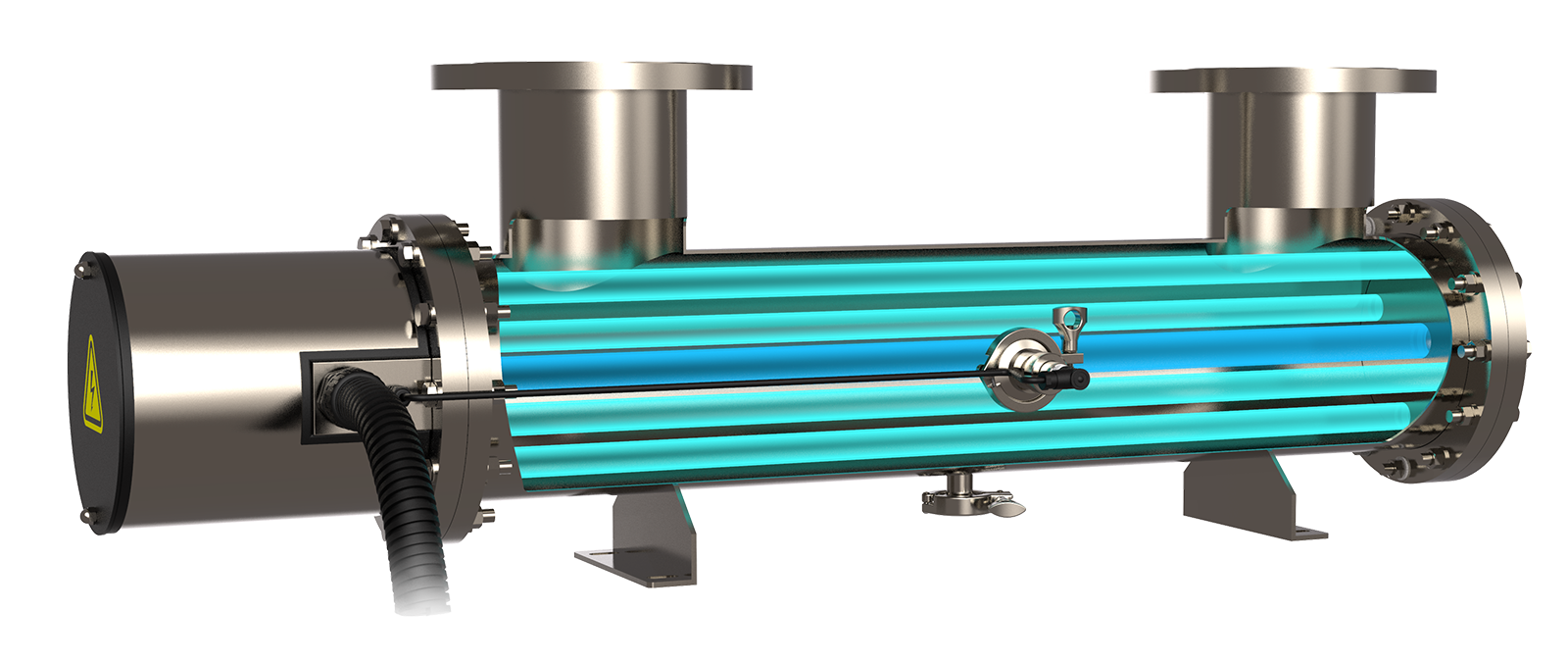

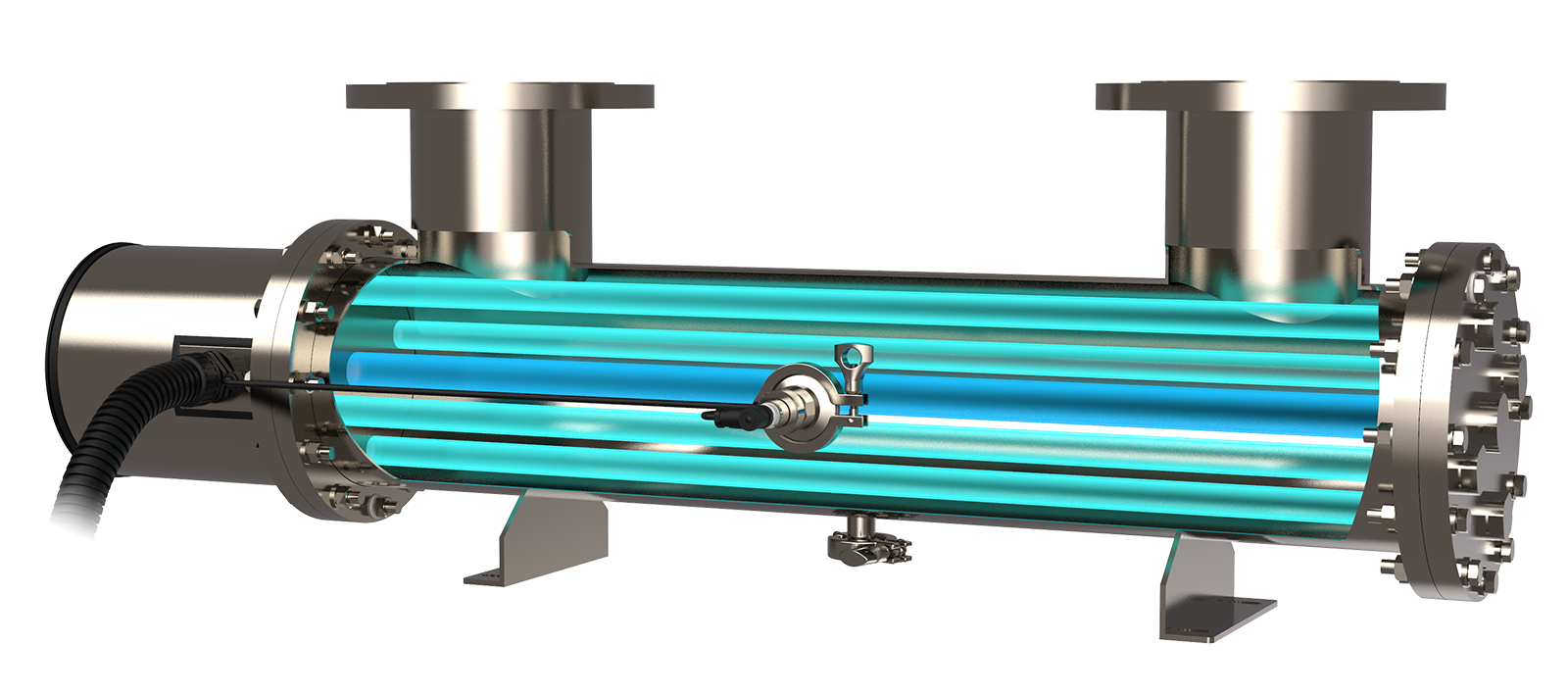

CoolPasTM Cold Sterilization system adopts LightDomeTM technology, is very effective in killing Mesophile like Lactobacillus and Enterobacterium, Thermophile bacteria like streptococcus thermophilus and Bacillus Stearothermophilus, Psychrophilic bacteria like Pseudomonas and Leukonoid, as well as spores and Pathogenic bacteria. The system can achieve 360º rotation during the disinfection process, which could thoroughly disinfect the product by avoiding hindrance by fruit meat in the juice and the dark material in the fluid. Moreover, the system can disinfect the process water together with Sugar and Juice at the same time. The innovated baffle design could distribute water evenly in the chamber to avoid dead corner, which will reduce both the capital cost and running cost of the system significantly.

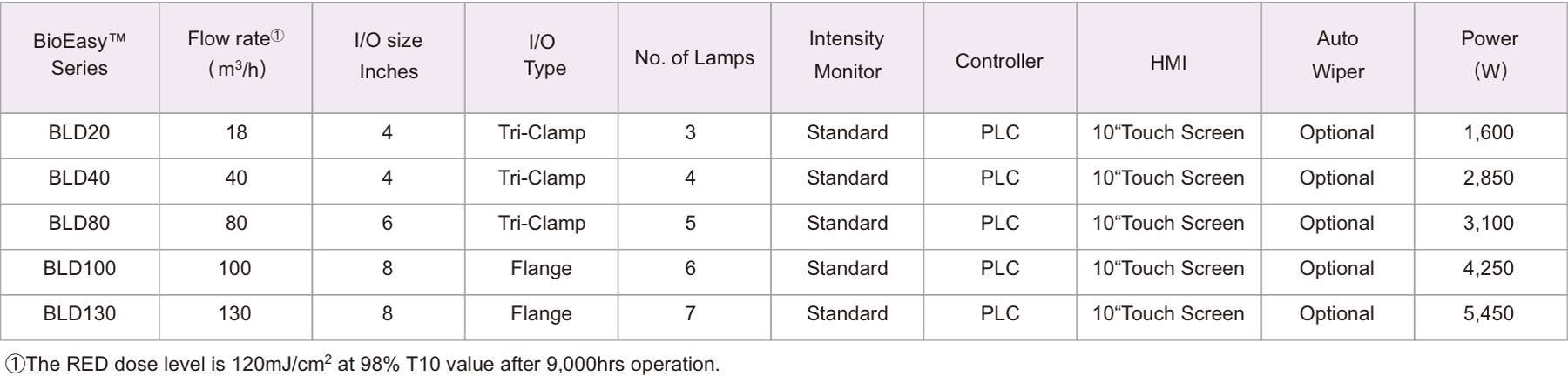

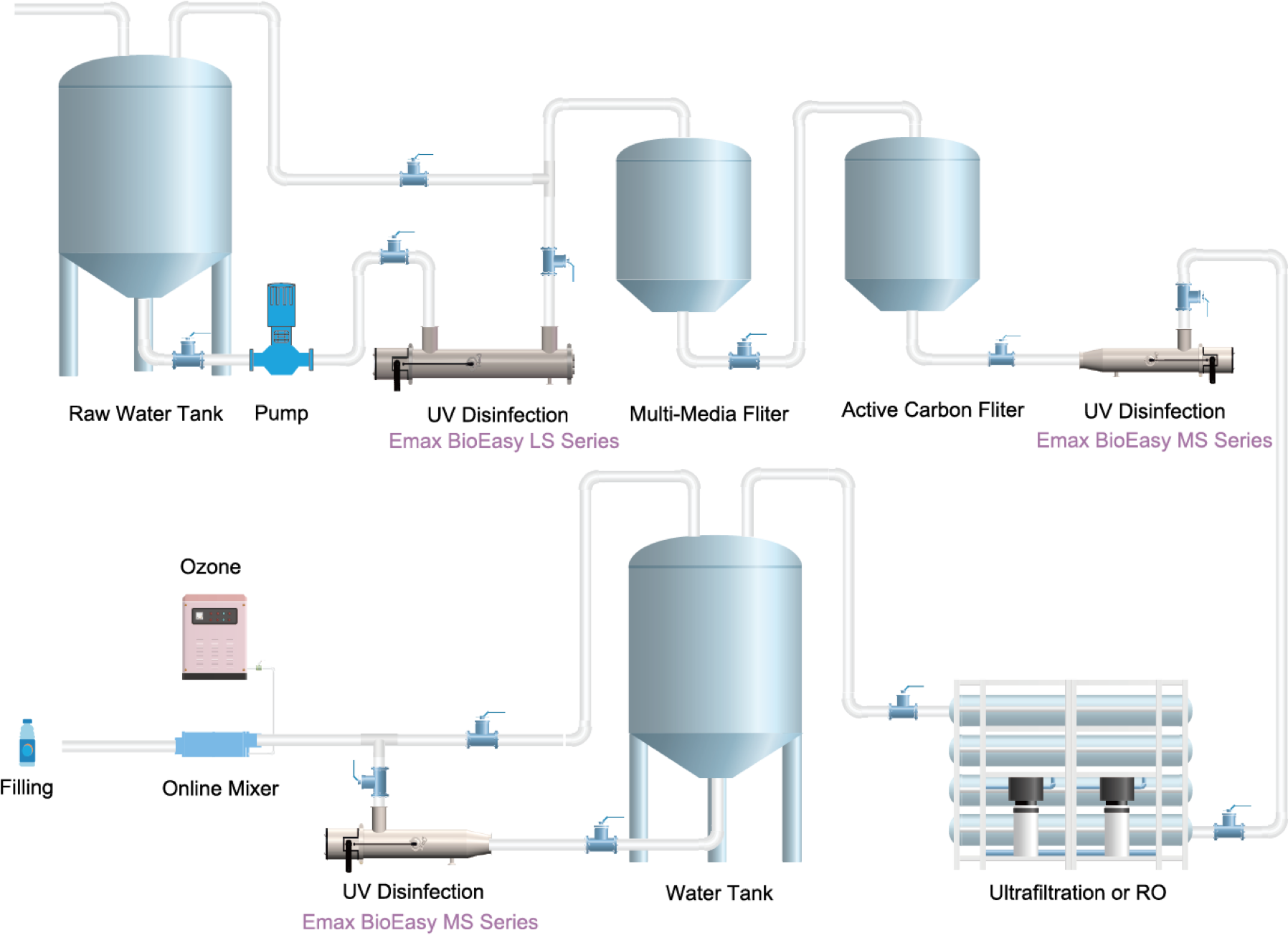

BioEasyTM Water disinfection system

he Deactivation of the Bacteria, Virus and Parasites with UV is mainly by destroying the nucleic acids of Microorganisms. The hereditary information critical for nucleic acids could be damaged by UV lights within 200-300nm UV then Microorganism can't reproduce. In addition, UV can also interact with water molecule and dissolved oxygen to generate Hydroxyl radical (OH·) to oxidize the protein enzymes and other parts of Microorganism.

UV dose is the key parameter to control the disinfection performance. The resistance level to UV variates among Microorganisms species, As an example, Fungal spores is more resistant to UV than bacteria spore. For general bacteria and spore disinfection, UV dose in the process shouldn't be lower than 40,000uw·s/cm2(40mJ/cm2), but if the target bacteria is unknown and several different bacteria species present in the water, the UV dose need to be 100,000uw·s/cm2(100mJ/cm2) or above.

BioEasyTM is very efficient to kill P. Aeruginosa, Clostridium Perfringens, E. Faecalis, Aspergillus Niger and Mucor Mucedo in the water, and achieve 5Log (99.999%) and above reduction rate at the right dosage.

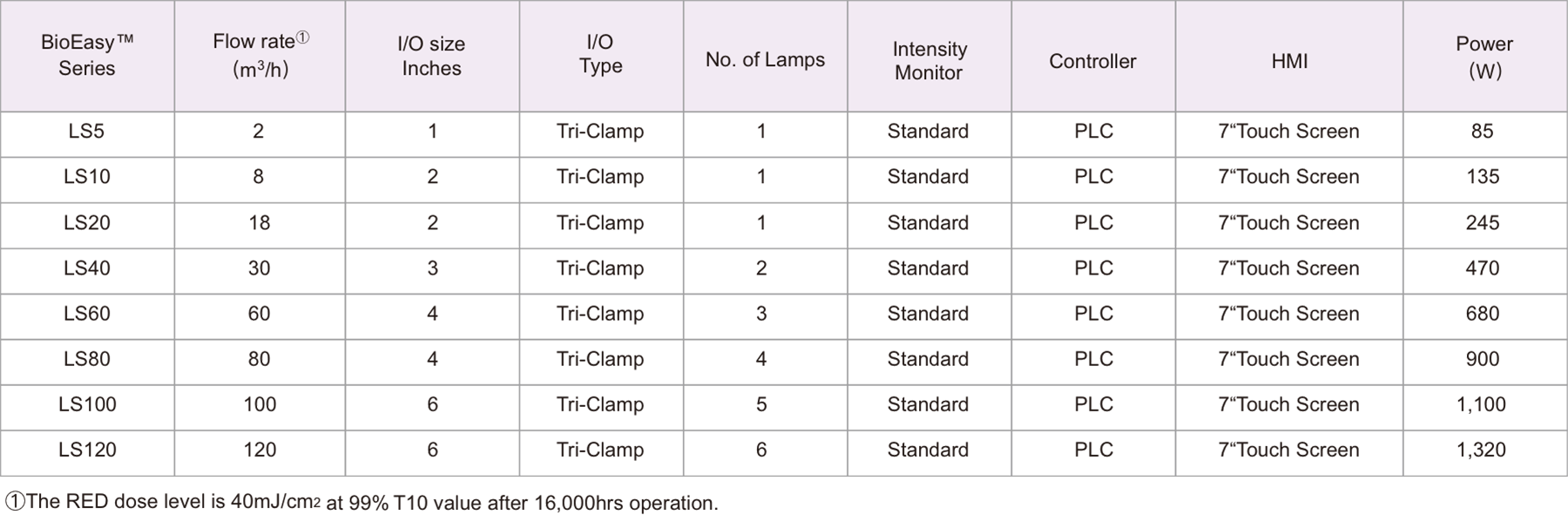

Low Pressure Amalgam LS series

Designed specifically for disinfection and low flow ozone destruction in Food & Beverage and Pharmaceutical industries, the system adopts the latest Amalgam lamp technology. The technology fully satisfies guidelines in ASME BPE, ISPE, and other international standards on sanitary equipment.

The chamber of the system is made of 316L SS. The system is equipped with UV intensity sensor to monitor real time UV dosage.

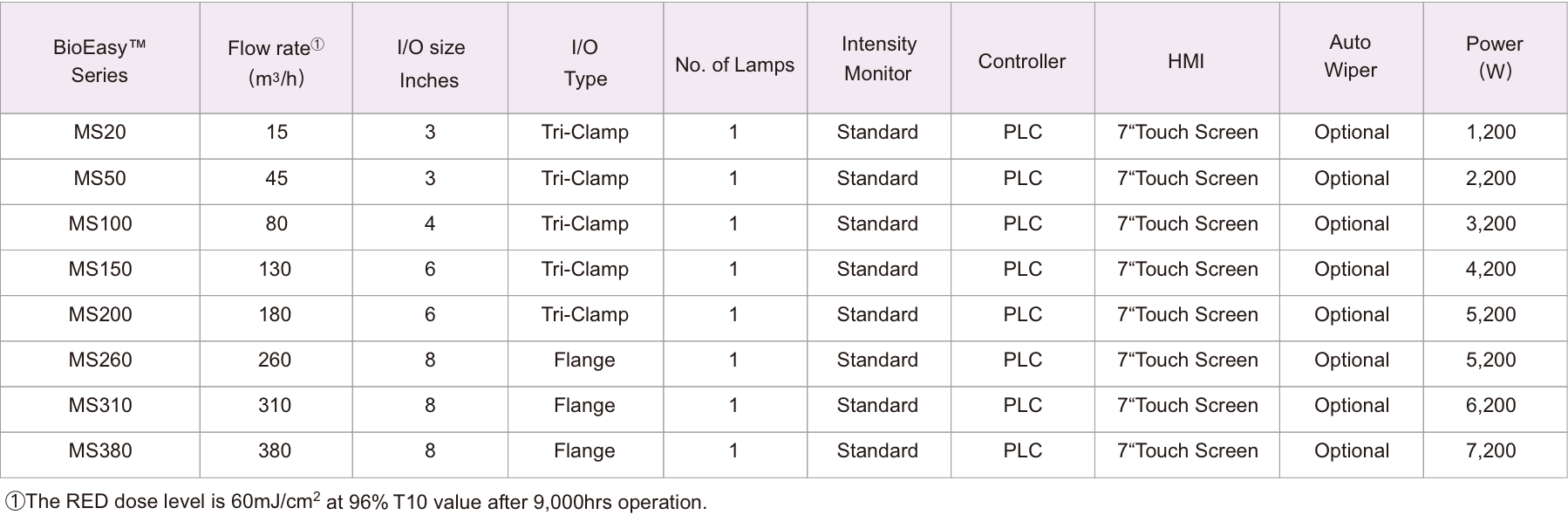

Medium pressure Broad wavelength system MS series

Advantages of medium pressure system include large power and broad wavelength, which are perfect for high bacteria load and the wide variety of species. The system can achieve high UV dose with a single lamp even at high flow rates. The design satisfies ASME BPE, and ISPE guidance on sanitary equipment.Customers can specify the real time dosage of the system based on microorganism species and the required removal efficiency. The electric ballast will automatically adjust the lamp power by the flow rate to stabilize the UV dose.

The chamber is made of 316L SS and auto wiper cleaning system is optional.

BLD Disinfection series with LightDomeTM technology

Adopting LightDomeTM technology, BLD series integrate medium pressure and low pressure UV technology in to one systems, which fully exploits the advantages of two technologies. The fluid to be treated will experience homogeneous UV exposure to avoid nitrite generation due to overdose when it passes through certain parts of the chamber.

BLD series will make the most of its advantages when flow rate fluctuates in a wide range, regulation on microorganism control is very stringent, as well as the tolerance for nitrite generation is extremely low. UV dose and combination ratio of different wavelengths can be set up based on the target microorganism amount and species complexity, required disinfection efficiency, and the incoming nitrate concentration. The system is equipped with independent power adjustment technology, which can adjust the power automatically to keep the UV dose constant when the flow rate and water quality change. The chamber design of the system design conforms to ASME BPE and ISPE standards.

The Chamber is made of 316L SS. Auto wiper cleaning system is an available option.